Are you looking for a compact, reliable solenoid valve to fit into your pneumatic automation setup without complicated integration?

Buy 1PCS Pneumatic Integrated Mini Solenoid Valve CPV15SB6F On Amazon

Product overview

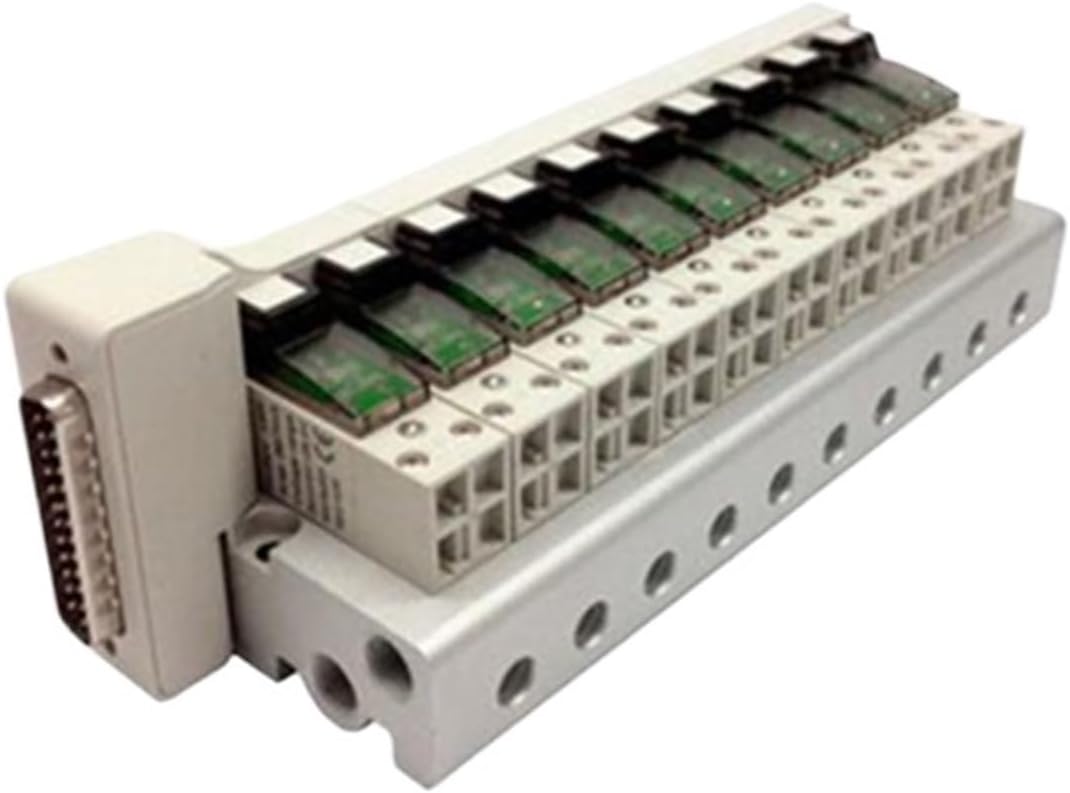

You’re looking at the 1PCS pneumatic integrated valve group mini solenoid valve CPV 15SB /F 1/8 control directional valve valve group automation (Color : CPV15SB6F), a small but capable pneumatic directional control valve intended for integrated valve group applications. This product is listed under Solenoid Valves › See more product details, and it’s designed to provide a compact control solution when you need several solenoid valves grouped or when panel space is limited.

What the product name tells you

The model name is long because it packs a lot of useful information: “CPV 15SB” is the series, “/F 1/8” indicates the fitting/port size, and “mini solenoid valve” tells you the general physical profile. You can use that label to match it to your existing manifolds and fittings; make sure you verify the CPV15SB6F color/version to confirm wiring and mounting specifics.

1PCS pneumatic integrated valve group mini solenoid valve CPV 15SB /F 1/8 control directional valve valve group automation (Color : CPV15SB6F)

Key specifications at a glance

You’ll want the basic specs up front so you can quickly decide whether this valve fits your system needs. Below is a concise summary of common specifications you should confirm with your supplier or datasheet before purchase, since small variations can matter for electrical, pneumatic, and mechanical compatibility.

| Feature | Specification (typical) | Notes for you |

|---|---|---|

| Model Name | CPV15SB6F (1PCS pneumatic integrated valve group) | Confirm suffix and color/version for compatibility |

| Valve Type | Mini solenoid directional control valve | Suitable for single or manifold-mounted applications |

| Port Size | 1/8″ (often PT or NPT equivalent) | Check thread type (PT, BSPT, NPT) before plumbing |

| Control Voltage | Commonly 24V DC or 110/220V AC variants available | Verify coil voltage on the product label |

| Number of Positions | 2-position or 3-position variants | Choose according to the control logic you need |

| Flow Rate | Moderate (suitable for small pneumatic actuators) | Not for large cylinders or high flow processes |

| Mounting | Manifold / integrated valve group mount | Works well in compact valve banks |

| Material | Aluminum body, plastic base, rubber seals | Typical materials — check for special media compatibility |

| Application | Automation, control of small actuators | Good for pick-and-place, small conveyors, clamping |

Design and build quality

You’ll notice the valve is deliberately compact to allow multiple units to be grouped together in a valve manifold, saving space and simplifying tubing. The build typically uses a mix of aluminum for the body and engineered plastics for the solenoid housing, giving you a balance of durability and lightweight construction.

Materials and finish

The exterior finish generally resists light corrosion and handles typical shop or factory environments without being overly heavy-duty. You should examine the seal materials (NBR, EPDM, or Viton) for compatibility with your working media and temperature range to avoid premature wear.

Functional performance

When you operate the 1PCS pneumatic integrated valve group mini solenoid valve CPV 15SB /F 1/8 control directional valve valve group automation (Color : CPV15SB6F), you’ll get quick switching suitable for small pneumatic actuators and control circuits. Response times are usually fast enough for typical automation cycles, but if you need millisecond-level precision, check the manufacturer’s response spec for the coil and spool.

Valve operation modes

These valves can be configured as 2-way, 3-way, or 5-way depending on the manifold and internal spool, enabling common pneumatic control patterns such as push-to-actuate, pilot release, or changeover. Make sure you know the exact valve configuration included in your purchase; the product listing might show a generic family of parts, and not every unit has the same internal porting.

Electrical and coil considerations

You’ll power the solenoid coil with the voltage variant you specify, typically 24V DC for modern control systems or 110/220V AC for simpler wiring. Always confirm coil polarity and whether a diode or suppressor is fitted — a missing diode could affect your control electronics or cause back EMF spikes that reduce relay and PLC lifespan.

Wiring and connectors

You’ll often find standardized connectors (e.g., DIN or molded leads) that make wiring straightforward, but check for the connector type before ordering replacement coils or mounting to a cabinet. For multiple valves in a group, wire routing and cable length become important to avoid electromagnetic interference and to keep labels clear for maintenance.

Purchase The CPV15SB6F Mini Solenoid Valve On Amazon

Pneumatic connections and plumbing

You’ll connect this valve using the specified 1/8″ ports; you should verify whether they’re BSP, NPT, or metric threads to ensure leak-free plumbing. For manifold mounting, the base and port orientation can change how you route tubing, so plan your tubing runs to minimize bends and pressure drops.

Gaskets, fittings, and sealing

Make sure to use the correct PTFE tape or thread sealant compatible with compressed air to avoid contamination of the air supply and to ensure a lasting seal. If you’re building a valve group, use the same thread standard across all valves and fittings to prevent cross-mating issues during maintenance.

Flow, pressure, and limits

These mini solenoid valves are optimized for moderate flow rates and moderate system pressures — typically up to 0.7 MPa (about 101 psi) for many models in this family. If your application needs higher flow or operates at higher pressures, you should select a larger valve or different series to avoid excessive pressure drop or premature spool wear.

Cyclic life and duty cycle

You’ll see best service life when operating within the recommended duty cycle; many mini solenoid valves are rated for continuous duty but have limits on how frequently they can switch without increased wear. Check for recommended lubrication of pneumatic circuits and avoid cycling them at extremes of temperature to prolong life.

Installation tips

You’ll get the best installation results when you mount the valve securely, keep the manifold and tubing tidy, and ensure proper electrical connections to the coil. Proper orientation and avoiding restricted exhaust paths are crucial — if an exhaust port is blocked, the valve may not return properly.

Mounting and orientation

Mount to a flat surface or use the manufacturer’s manifold or bracket for a clean, repeatable installation. If you assemble multiple units, keep consistent labeling and make space for future access so you or a technician can service them without dismantling the entire group.

Safety and compliance

You’ll need to ensure the valve and any control electronics meet relevant safety and regulatory requirements for your industry or region. Check for CE marking, RoHS, or other conformity indicators if compliance is a concern for your production or sale of final goods.

Electrical safety and grounding

Always isolate power before wiring or servicing the coil. If your system is subject to industrial standards, ensure proper fusing, grounding, and protective circuits are in place to prevent electrical faults from cascading into larger failures.

Common applications and use cases

You’ll typically find this valve useful in small automation tasks such as actuating grippers, controlling small cylinders, or sequencing operations in lab automation. Its compact size makes it ideal when you want to build a compact valve bank near the point of use.

Hobbyist and maker projects

If you’re working on a prototype or a small-scale production, this valve is often affordable and easy to work with, making it a popular choice for hobbyists and small workshops. Keep in mind that hobbyist use still demands careful matching of voltages and the correct thread types.

Maintenance and troubleshooting

You’ll want a regular maintenance schedule that includes visual inspection, leak checks, and cleaning of filter regulators to extend service life. Address common issues like worn seals, dirty orifice areas, and electrical coil failures early to avoid unexpected downtime.

Simple troubleshooting steps

If a valve doesn’t actuate, check the coil voltage first, then confirm that compressed air is reaching the supply port and that exhausts are clear. Replace seals or the spool if you notice internal leaks or inconsistent actuation; many valve groups allow you to swap out individual units without emptying the entire manifold.

Pros and cons — quick evaluation

You’ll appreciate the compactness and ease of grouping these valves, but you should be aware of limitations in maximum flow and pressure compared with larger industrial valves. Below is a quick list to help you weigh whether this particular mini solenoid valve fits your needs.

- Pros: space-saving, cost-effective for small systems, easy manifold integration, common coil voltages available.

- Cons: limited flow capacity, variable thread standards across vendors, potential need for specific connectors or diodes.

How to choose the right variant for your application

You’ll choose based on port/thread type, coil voltage, valve position/configuration, and seal material compatibility with your working media. Confirm the exact CPV15SB6F variant before ordering to make sure the valve’s electrical and pneumatic interfaces match your system.

Sizing for flow and pressure

Pick a valve whose flow coefficient (Cv or Kv) and maximum pressure rating exceed the demands of your actuator and line length. Undersizing will starve your actuator and lengthen cycle times, while oversizing can increase cost unnecessarily.

Comparison with similar products

You’ll find that many vendors offer mini solenoid valves with similar dimensions and claims, but quality, tolerances, and available options such as manual override and feedback switches differ. Compare leaktightness ratings, cycle life numbers, and whether a valve comes with a pre-assembled connector or requires separate purchase.

When to choose a larger valve

If you need higher flow, higher pressure capability, or more robust porting options (for example, 1/4″ or 3/8″), a larger valve series will serve you better. Larger valves also often offer higher duty cycles and longer cycle life under heavy industrial use.

Installation checklist

You’ll save time and headaches by inspecting the valve on arrival, confirming the coil voltage, verifying thread types, and checking for any shipping damage. Keep spare seals and a spare coil if your operation is critical and you want fast replacement.

Tools and consumables to have on hand

Have PTFE tape or proper thread sealant, small wrenches for tightening 1/8″ fittings, a multimeter for verifying coil voltage, and a pressure gauge to confirm supply pressure. Labeling materials are also useful to mark coils and tubing so future troubleshooting is quicker.

Real-world performance expectations

You’ll generally get reliable operation for light-to-moderate pneumatic control tasks, with response times suitable for typical automation cycles. Expect that environmental factors, such as dust or temperature extremes, will affect life span unless you take protective measures.

Environmental considerations

If your valve will live near dust, moisture, or corrosive atmospheres, consider adding protective enclosures or choosing valves with higher IP ratings. For clean-room or food-grade applications, make sure seal materials and lubricants are acceptable for your standards.

Buying tips and vendor questions

You’ll want to ask vendors for the exact datasheet for the CPV15SB6F variant, including electrical wiring diagrams, coil power consumption, and recommended service intervals. Confirm return policies, warranty coverage, and whether a sample unit is available if you’re qualifying the part for a production line.

What to check in the listing

Verify the stated port thread standard, coil voltage, and whether the shown image exactly matches the item you will receive; some listings use a family photo. If you need matched manifold mounting holes, confirm that bolt patterns and gaskets are included or sold separately.

Troubleshooting common faults

You’ll want to follow a logical method: check power, then air supply, then mechanical binding, and finally internal seal or spool issues. Common symptoms like sluggish actuation often point to contaminated air or insufficient pressure, while total failure to actuate is often electrical.

When to repair vs replace

If the coil is burned or the spool is severely pitted, replacement is usually faster and more reliable than attempting a field repair. For low-cost mini valves, keeping spares on the shelf and swapping units tends to be more economical in a production environment.

Frequently asked questions (FAQ)

You’ll often ask whether the valve comes with a mounting bracket, what thread type is used, and whether the coil is included. Always confirm these points up front, as some sellers separate the valve, coil, and connector into different SKUs.

- Q: Is the coil polarity-sensitive? A: Many DC coils are polarity-insensitive but some have built-in diodes — check the datasheet to be sure.

- Q: Can I use this with vacuum? A: Some directional valves can be used for limited vacuum service, but check leakage and seat design first.

- Q: Are replacement coils available? A: Yes, most vendors sell replacement coils, but confirm the voltage and connector type match your unit.

Final recommendation and verdict

If you need a small, interchangeable solenoid valve for compact pneumatic automation, the 1PCS pneumatic integrated valve group mini solenoid valve CPV 15SB /F 1/8 control directional valve valve group automation (Color : CPV15SB6F) is worth strong consideration because of its space-saving design and common interface options. Make sure you verify the specific variant’s coil voltage, thread standard, and seal material so that it integrates smoothly into your system and delivers the reliability you expect.

Short purchasing checklist

Before you order, confirm: coil voltage and connector type, port thread standard, spool type/positioning, seal material, and whether mounting hardware is included. Having these items confirmed will reduce the chance of returns or last-minute mismatches and help you get your pneumatic system running quickly.

Get The 1PCS CPV15SB6F Pneumatic Mini Solenoid Valve — Amazon

Disclosure: As an Amazon Associate, I earn from qualifying purchases.